Impulsione a Condição do Navio Monitoramento e a Eficiência do Diagnóstico com Emdoor 10 Inch Rugged Tablets

Projeto

Antecedentes

O plano de manutenção tradicional do equipamento rotativo de um navio exige que o navio pause sua operação uma vez a cada 5 anos ou, em alguns casos, com mais frequência por um mês ou até mais e realize uma inspeção abrangente de desmontagem de equipamentos. Longos períodos de manutenção reduzem a eficiência operacional da embarcação. Portanto, o monitoramento de condições com uma tecnologia não destrutiva, como análise de vibração, que pode simplificar a inspeção do navio e encurtar a janela de manutenção, tornou-se a melhor solução para ajudar os armadores e as empresas de gerenciamento de navios a manter a competitividade do setor.

Solução

The Emdoor EM-I10J 10-inch rugged tablet windows 10 provides the most cost-effective option for efficient ship inspection, as it has a fully rugged shell, and is salt spray tested, certified to U.S. Military-810G and IP65-rated for water and dust resistance. It’s easy to use in offshore environments where corrosive electronics exist. Another key factor in choosing the I10J tablet is that it has a high-performance Intel quad-core processor that is perfectly compatible with the HAT Analytics 2nd generation digital health monitoring system Ad|Vi|Se, guaranteeing stable diagnostics.

Benefícios

Compared with the traditional maintenance methods, the intelligent ship condition monitoring solution brought by the cooperation of the I10J tablet and the HAT Analytics digital health monitoring system Ad|Vi|Se provides a faster, more effective and reliable predictive ship machinery maintenance mode. Through portable data collection, instant health condition analysis and diagnostics, unplanned downtime and malfunctioning equipment issues are forewarned and repaired, preventing costly and time-consuming catastrophic failure events.

Desafio

-

A operação normal de um navio depende da disponibilidade de máquinas a bordo, e a manutenção regular é necessária para garantir que o navio esteja sempre em boas condições. A manutenção tradicional do navio do equipamento rotativo é baseada em aberturas regulares a bordo ou em um estaleiro, o que requer transporte de desmontagem e inspeção profissional. Assim, os navios precisam sair do negócio até que a manutenção seja concluída. A carga de trabalho é grande e demorada, o que aumenta a pressão sobre a empresa de navegação. No entanto, os programas de manutenção preditiva podem transformar a manutenção de reativa para proativa, evitando possíveis falhas com detecção precoce de problemas, aumentando a vida útil do equipamento e encurtando as janelas de manutenção.

- A HAT Analytics, fornecedora líder de serviços de manutenção preditiva, oferece soluções inovadoras de monitoramento digital que exigem a assistência de dispositivos robustos de computação móvel. Como a operação offshore, onde temperaturas extremas, choque, vibração e ar salgado são comuns, equipamentos excessivamente frágeis podem aumentar o alto custo da substituição de hardware. Qual computador móvel é a melhor escolha? Para encontrar essa resposta, a HAT Analytics realizou uma extensa pesquisa por tablets de aquisição de dados que atendem aos padrões de comunicação.

Solução

-

Emdoor's EM-I10J industrial tablet is an ideal choice for HAT Analytics 2nd generation of digital health monitoring system Ad|Vi|Se. As part of the overall solution, its robustness and powerful computing power allow the digital health monitoring system to stably perform real-time monitoring and diagnosis of the ship's mechanical status.

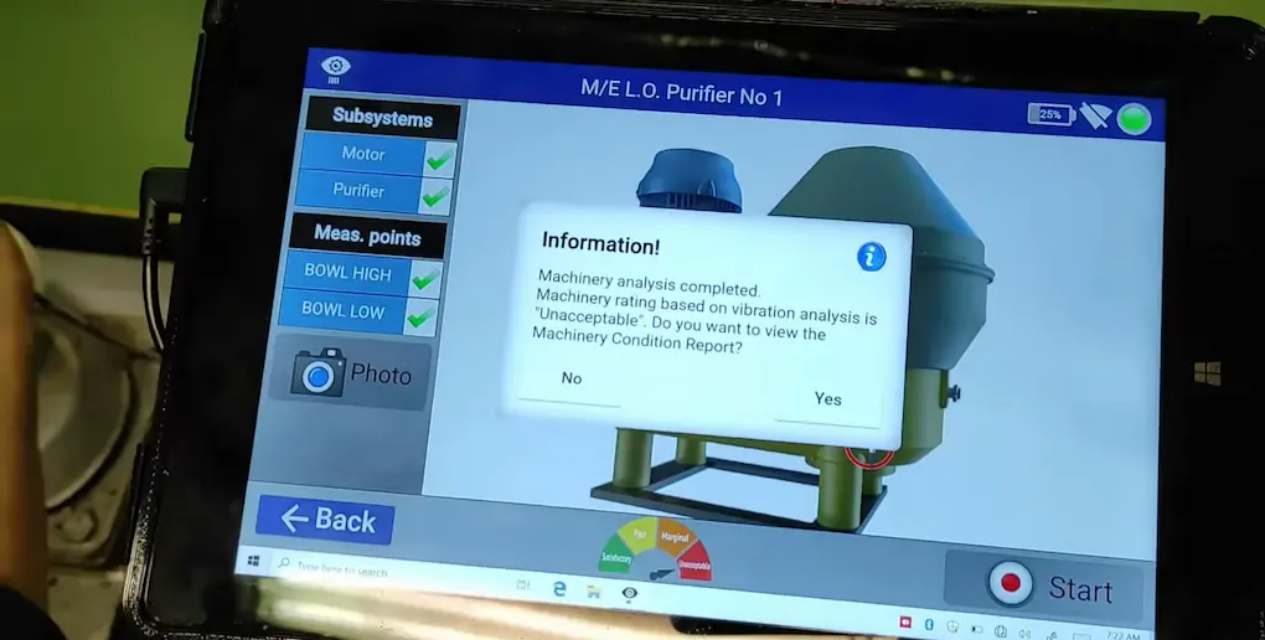

- The EM-I10J industrial tablet windows, which operate in cooperation with the HAT Analytics digital health monitoring system Ad|Vi|Se, convert the collected vibration data into an easy-to-understand health report which is presented to the crew via a highly interactive user interface. With the intuitive data display, crews can get measurement results and locate the root cause of the fault faster, and maintenance can be carried out more quickly. Meanwhile, the inspection report will also be automatically generated and transmitted to the cloud server for validation and machine learning modelling through the low-latency network of the EM-I10J tablet. This increases the reliability of the health monitoring system and through the AdViSe CM Dashboard the ship's superintendent and fleet manager can securely access the information and several condition monitoring metrics of the fleet from anywhere. In the face of difficult mechanical problems, the staff can take pictures of abnormal equipment through the EM-I10J high-definition rear camera, and feed them back to the cloud to seek help from remote analysis and diagnosis by the HAT team of experienced engineers.

Benefícios

-

EM-I10JThe EM-I10J rugged tablet meets all HAT Analytics expectations for the Ad|Vi|Se device performance and durability, giving technicians the stable platform they need to inspect, debug and troubleshoot in a variety of situations, allowing them to further their work maintenance tasks.

-

Resistente ao spray salinoO ambiente marinho envolvendo exposição ao sal é um enorme desafio para os equipamentos computacionais. Emdoor EM-I10J robusto tablet windows fornece tecnologia anticorrosiva única, seu design de porta selada pode evitar danos salinos ao sistema durante o processo rigoroso de teste de spray salino a longo prazo, reduzindo os custos adicionais causados por falhas no computador e interrupções no trabalho.

-

Resistente à temperatura extremaO EM-I10J é capaz de trabalhar em uma ampla faixa de temperaturas de-20 a 60 graus Celsius, o que também é crítico para técnicos offshore. Como eles geralmente precisam trabalhar em calor extremo no mar, luz solar direta e outras condições climáticas adversas, o I10J, como ferramenta auxiliar, precisa enfrentar as duras condições de trabalho com eles para fornecer um serviço confiável no local.

-

Eficiente conexão dadosAs vantagens que o tablet robusto oferece aos sistemas de 2ª geração da HAT Analytics não são apenas sua durabilidade, mas também sua conexão de rede estável. A transmissão de rede de alta qualidade do EM-I10J acelera o tempo que leva para os técnicos de campo acessarem dados de diagnóstico e tomarem decisões de diagnóstico remoto, permitindo que eles trabalhem com um nível mais alto de eficiência de campo.